AUTOMATION SYSTEMS

The LANG company has been developing step motor controls for fine positioning for almost 40 years. In this scope, the micro-step was a milestone in the development. This technique was already developed by LANG in the seventies. This long-term experience also benefits the high-class LANG motor controllers, which are developed in collaboration with our customers. They are high-resolution step motor controls for 2/4 phase step motors. The dynamic micro-step operation enables very fast positioning processes with the highest accuracy.

1.Positioning systems

Motion Control

LSTEP express

Controllers of the LSTEP express product family make it possible to control 2 and 3 phase stepping, servo, and linear motors as well as DC servo motors with one (motion) controller. In servo operation, a user-friendly automatic controller dimensioning is possible with only a few parameters. Up to 4 axes can be driven. For all axes motor currents from 0,2 to 20 A are possible. Our software WIN-Commander also allows user-specific configuration of LSTEP express. Thus all your different requirements can be realized flexibly according to your individual needs with one single positioning system.

LSTEP PCI express

A wide range of equipment options provides more flexibility, allowing you to adapt the system to meet your individual needs. The free LANG API allows the integration into your own software environment. Controllers from LANG are also available as OEM devices with your own company logo.

We also offer complete axes and handling systems – everything from one source!

LSTEP

High-resolution stepping motor controller for controlling up to three axes with 2/4 phase stepping motors. The dynamic micro-step operation allows positioning operations to be done very quickly with the utmost precision.

The convenient user interface Win Commander provides even more operational functionality via the serial interface.

A wide range of equipment options is available for even more flexibility, allowing you to adapt the system to meet your individual requirements. The free LANG API allows the integration into your own software environment.

LSTEP-PCI compact

The LANG LSTEP-PCI compact Positioning System is a high-resolution stepping motor controller in the form of a PCI plug-in module for the PC. This device is used to control three axes with 2/4 phase stepping motors. Communication between the PC and the controller takes place through the PCI bus topped by a Dual-Port Ram or the RS 232 interface.

Dynamic micro-step operations allow positioning processes to be done quickly and with the highest precision. The small dimensions of the PCI-board allow integration in nearly every PC-housing.

.

LSM Synchronous Servometers

The motors are characterized by a low moment of inertia, compact design, high dynamics, and high reliability. Due to the mechanical design, the motors have a very low torque ripple.

The motors are particularly suitable for applications in which dynamic positioning processes are required, coupled with smooth running and precision.

Options available:

- feedback systems: 1Vss

- retaining brake

- key groove

- various plug-in versions

Further options and design modifications of the motors according to customer requirements are available on request. LANG supports you with the configuration and selection of the right motors for your application.

2.Servomotors

-

Handling machines

-

Machinery- and plant engineering

-

Mechanical engineering

-

Measurement and testing technology

-

Microscopy

-

Imaging systems

-

AFM microscopy

-

Wafer inspection and wafer handling

-

Test and analyzer systems

-

Micro assembling

-

Laboratory automation

-

Medical technology

-

Image processing

-

Clean room applications

Application Areas

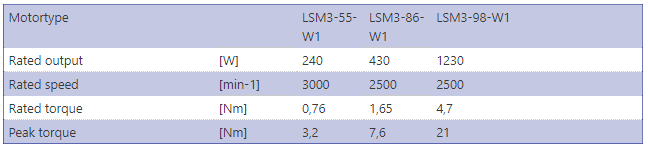

Technical data LSM Servomotors

3.Linear axis

LT series

The cheap linear stages of the LTM 80 series are suitable for applications in continuous operation as well as fitting in machines. The special guides make sure a practical slip-stick-free drive and high capacity. Because of the combination of the material in the elevating screw and the screw nut we can assure low abrasion and high durability. All aluminium components have a high quality black Eloxal-coating.

LTM series

The cheap linear stages of the LTM 80 series are suitable for applications in continuous operation as well as fitting in machines. The special guides make sure a practical slip-stick-free drive and high capacity. Because of the combination of the material in the elevating screw and the screw nut we can assure low abrasion and high durability. All aluminium components have a high quality black Eloxal-coating.

6.Lift stages

HT Series

The precision lift stages are used where components and assemblies are measured with the highest accuracy or for positioning. The free-from float pre-stressed ball bearings guarantee a high true running accuracy. A step-motor is included in the basic version.

HVM Series

The established height lifting tables HVM 100 have a low height and high repeatability. Because of the prestressed guides, smooth drive and a high capacity are possible. All aluminium parts have a high-quality black epoxy-coating, making the lifting table capable for the industry. The maximum range is 30mm.

The LANG product range also includes accessories for controller e.g.

-

microscope stages

-

measuring tables

-

motorized tables

-

cross-tables

-

lift stages

-

linear axes

-

stepping motors

-

and much more.

ECO-STEP

The LANG positioning system ECO-STEP is a high-resolution stepping-motor control for three or six axes equipped with 2/4 phase stepping motors. The dynamic micro-step operation enables fast positioning movements with high accuracy. ECO-STEP connects to your PC via USB port or the optional Serial RS 232 Interface.

The integration of the controller and power amplifiers in one compact housing enables the setup of a cost-efficient complete system.Our software WIN Commander also allows the user-specific configuration of ECO-STEP. The free LANG API allows the integration into your own software environment.

LSMART express

The devices of the LSMART express product family consist of an intelligent master and four powerful drives with continuous output power of up to 400 W and considerable higher short-time peak power. Through the wide range of functionalities, a huge scope of applications is enabled by this synchronous point-to-point positioning system. This can easily be achieved by using the appropriate parameters and instructions of the extensive command set. Smooth and dynamic movements can be achieved through separate adjustments of acceleration and deceleration phase considering the desired speed and jerk.

For exact controlled movements

GT series

From low-cost to high-end cross tables, LANG offers a huge spectrum of cross tables for different application areas in different price categories. LANG offers different drive systems. As drive systems smoothed or rolled ball screw drives, lead screws, belt drives, or linear motors are used.

Crosstables are used where probes have to be analyzed, e.g. wafer inspection, microscopy as well as imaging systems. One big advantage is the easy integration into own systems. LANG cross tables are driven by high-class stepper motors.

The cross-tables in the GT series are consistently geared to the highest precision standards enhanced by pronounced rigidity. The comparator-adapted arrangement of the high-resolution measuring systems and the prestressed, backlash-free ballscrews between the junction roller guides combine to reduce positioning errors to a minimum. The extra rigid monolithic construction ensures outstanding reproducibility. On account of this compact design, which rules out risks of crushing while facilitating cable layout towards one side, the tables in the GT series are particularly suitable for open systems imposing exacting demands on operational and positioning accuracy.

4.Cross tables

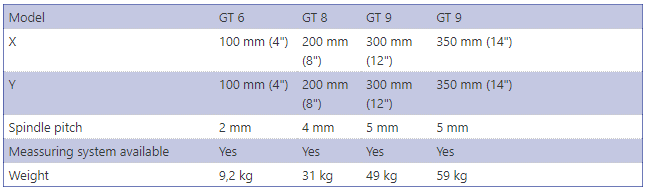

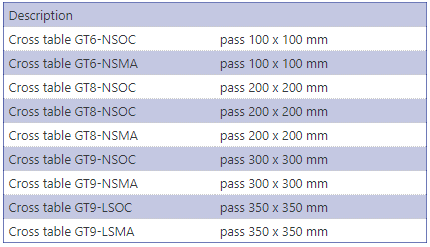

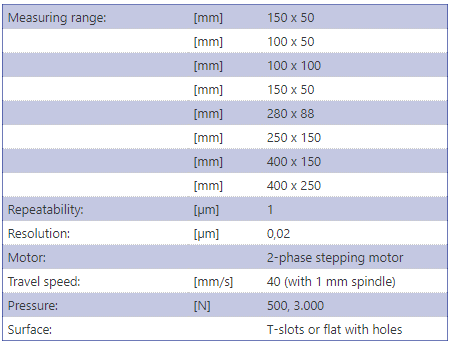

Technical data GT series

Models GT series

LHT series

The LHT series from LANG can be used for hardness testing and it can endure a lot and makes also a good visual impression. Of course, the crosstables can be used where high precision is needed or for industrial application.

Tables of the LHT series are characterized by a low height and high repeatability. With a maximum pressure capacity of 3.000N, the tables are particularly suited for tests with high impression forces. All aluminum parts have a high-quality black anodizing protective layer, which makes industrial use of the tables possible. The maximum range is 400 x 150 mm. The top plate can be equipped with T-Slots or holes for different clamping methods.

LANG offers different types of LHT tables – Please ask us for your table.

5.Hardness testing tables

Technical data Hardness testing tables

From low-cost to high-end lift stages LANG offers a huge spectrum of lift stages for different application areas in different price categories. LANG offers different drive systems. As drive systems smoothed or rolled ball screw drives, lead screws, belt drives, or linear motors are used.

Lift stages are used where fine moves in the z-axis are requested, e.g. wafer inspection, microscopy as well as imaging systems.

HT4 and HT7

HVM 100

7.Rotary systems

From low cost to high-end rotary stages LANG offers a huge spectrum of rotary stages for different application areas in different price categories. LANG offers different drive systems. As drive systems smoothed or rolled ball screw drives, lead screws, belt drives, or linear motors are used.

Rotary stages are used where probes have to be justified, e.g. wafer inspection, microscopy as well as imaging systems.

DMT 200

This precision rotary measuring stage allows unlimited rotation angles at resolutions of less than one angular minute. It is suitable for horizontal and vertical rotational axes.

The precision ball bearings and the worm gear drive are preloaded, to allow a nearly backlash-free positioning. All aluminum parts have a top-quality black anodized protective coating.

RT Series

The RT series of our precision rotation stages are used where rotation-symmetric components and assemblies are measured with the highest accuracy or for positioning. The free-from float pre-stressed ball bearings guarantee a high true running accuracy. A step-motor is included in the basic version.

DMT 130

This precision rotary measuring stage allows unlimited rotation angles at resolutions of less than one angular minute. It is suitable for horizontal and vertical rotational axes.

The precision ball bearings and the worm gear drive are preloaded, to allow a nearly backlash-free positioning.

All aluminum parts have a top-quality black anodized protective coating.

DMT 65

This precision rotary measuring stage allows unlimited rotation angles at resolutions of less than one angular minute. It is suitable for a horizontal and vertical rotational axe.

The precision ball bearings and the worm gear drive are preloaded, to allow a nearly backflush-free positioning.

All aluminum parts have a top-quality black anodized protective coating.