LANG SOFTWARE

Software from LANG

The unique software programs from LANG support the realization of ideas and requirements. LANG software products enable flexible combination of different machining strategies according to the production requirements. The easy handling and the online assistance of the LANG software tools help to reduce the production costs and the processing time and help to increase the productivity. All software products of the LANG family are compatible and allow a high level of creative freedom.

1.CAD/CAM Software

There´s no better way to realize your ideas!

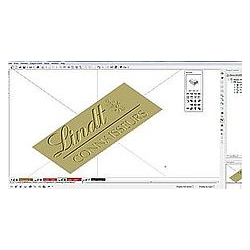

LErgoCAD

LErgoCAD – the all in one software from LANG under Microsoft® Windows™.

This software will allow you to produce CAM data for the output at your engraving and milling machine quickly and flexibly to suit your particular job

and your production capabilities.

The comfortable controls, as well as the easy user guidance, will help you to reduce production costs, decrease throughput times and provide a greater economy.

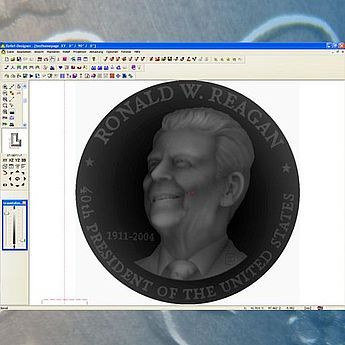

Relief-Designer

Extremely powerful software designed for Microsoft® Windows™ with a multiplicity of functions for relief designing, relief machining and the production of milling data.

Relief-Designer is fully compatible with the other software packages of LANG. Relief-Designer can also be combined with LANG digitization systems.

Relief-Designer is also available in the software package CAD+Design (including LErgoCAD).

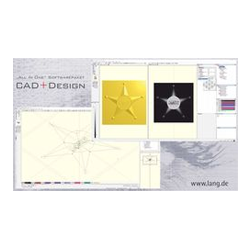

CAD+Design

CAD+Design is an "all in one" 64-bit software package consisting of LErgoCAD and Relief Designer, which now interact simultaneously. Changes made in one program are automatically reflected in the other program. The saving and opening of the LG3 file needed for the stand-alone versions of the programs are no longer necessary.

A button in the taskbar allows you to quickly switch between the programs. This connection is time-saving for the user and error sources are minimized.

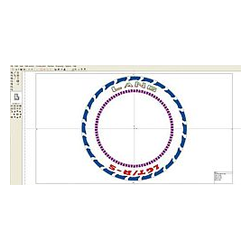

LTire Design

LTire – Software under Microsoft® Windows™ for fast and efficient construction of the total design of a tire sidewall mould and for LANG 4-axis machines for rotationally symmetrical round moulds (LGT, LGT-S, LGR, LGR-S).

The program offers the usual CAD functions and beyond that a lot of automated functions, particularly optimised for designing tire sidewalls.

.

Relief-Designer Scan

Digitizing program for LANG digitization systems. This software program is made for the digitization of free form surfaces and relief models with a laser scanner.

2.Digitalizing Software

-

3D digitization of free form surfaces

-

User-friendly wizards and dialogs

-

Select and digitize concept to digitize parts of the relief

-

The actual measuring range (focus position of the sensor) can be found automatically

-

Users can specify the desired X, Y resolution through the software

-

Digitization report (e.g. start, end time)

-

Digitization summary in relief file

-

Verify Z position for digitization

-

Digitization area can be entered through the keyboard or by „Teach-In“ with laser

-

Automatically storage of the surface data after digitization

-

Possibility of saving and reloading all parameters of digitization.

-

Digitization is possible in different shapes - Rectangle, Circle or Polygon

-

Several different materials can be digitized in sequential order or in a single start

Highlights

-

Marking of individual relief points or relief areas

-

Modification of the scanned values (individual points, marked areas)

-

Various filter functions (total relief, marked areas) for the handling of the scanned relief data

-

Relief transformation (Mirroring, Rotating, Moving, Scaling, Shearing, Inverting)

-

Comfortable display functions as Grey steps, Rainbow view, Isohypses view or Lighting simulation

Processing functions:

3.Output Software

LTire M

Output program under Microsoft® MS-Windows™ for rotation profile symmetrical moulds on LANG 4 axes machines.

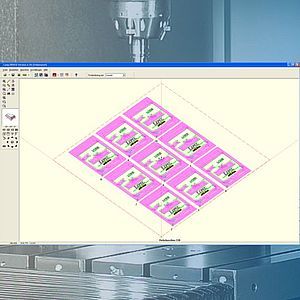

LDriver

Standardized 3D output and handling software for Microsoft® Windows™ for all LANG CNC milling and engraving machines, as well as laser engraving machines. The comfortable user interface with graphic visualization of CAM data simplifies substantially the machine operation.

On the one hand, complete manufacturing projects can be provided in the production planning stage; on the other hand, the production parameters for a repeat engraving order can be adapted easily and quickly.

4.Controller Software

Win - Commander

Win - Commander is a menu-driven development system for the WINDOWS environment. It simplifies the control and programming of the LANG positioningsystems as there are MCL, ECO-STEP and LSTEP. All necessary parameters i.e. spindle-leads, maximum values etc. may be entered in SI-units via menus and then transferred to the respective control units.The complete command set for the positioning-systems is available via mouse-click. In addition the creation and execution of complex axes movements may easily be performed.

LANG API

The application development system for LANG API avoids a large library (DLL) to approach the LANG positioning systems of the following type series LSTEP express, LSTEP, ECO-STEP, and MCL. The application development system includes many functions to use the huge functional range of the controller without detailed knowledge of the instruction set.

Furthermore are all necessary header files are included to include them in the different programming languages. The documentation of the different instructions is part of the scope of delivery.